How We Build The Ultimate Pontiac V8 — Yours. |

|

Sure. Pontiac V8 engines have their similarities to other, more common engines. But they have plenty of differences, too. Differences that folks who rebuild Chevys, Fords, and Mopars each day typically don't know. Differences they won't learn rebuilding only one or two Pontiac V8s a year. When it's time to rebuild your special Pontiac's V8, you should only entrust it to folks who specialize in Pontiac V8s. PONTIACS ARE ALL WE DOAt Nitemare Performance we only rebuild classic Pontiac engines, like the legendary 389, 400, 421, 428 and 455 cubic inch V8s produced from 1955 through 1981, including all the Tri-Power, H.O., Ram Air, and Super Duty variants! Not only do we know Pontiac V8s inside and out, but we know all the tips and tricks to develop maximum power in a durable, reliable combination for your classic Pontiac. Our focus on pure Pontiac engines has lead us to develop some of the most innovative Pontiac-specific upgraded components and street- and track-tested preparation and assembly techniques that deliver optimal performance, efficiency, and reliability. And we invest heavily in state-of-the-art, hyper-accurate tooling and equipment like our new Rottler S85A CNC-controlled resurfacing machine (right) and Rottler SG7MTS seat and guide station to precisely prepare your block and cylinder heads to be rebuilt. Our attention to detail and obsessive commitment to quality has resulted in Nitemare Performance engines being featured in numerous magazines and under the hoods of some of the finest Pontiac show and race cars in the nation. Let us build one for your Pontiac. |

|

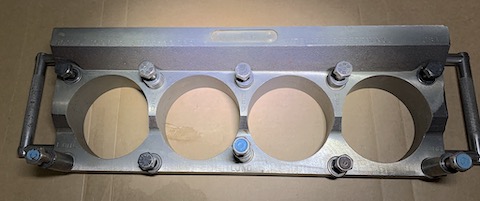

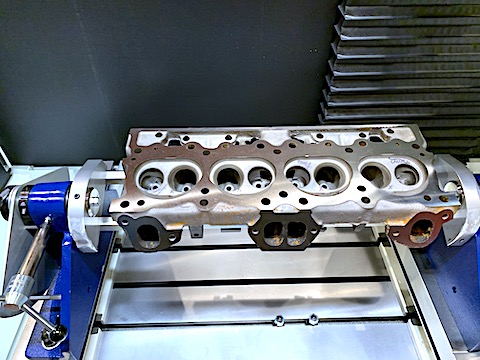

ANYTHING WORTH DOING ... Our motto is: Anything worth doing is worth overdoing. When it comes to rebuilding Pontiac V8s, that means ensuring that your Pontiac block and heads are sound and dimensionally accurate, then meticulously measuring and assembling each component by hand in our cleanroom facility. We start by thoroughly cleaning all the components of your Pontiac V8 that will be re-used, so they can be thoroughly and accurately inspected, tested, and prepared. METICULOUS BLOCK PREPARATIONAny decent shop will Magnuflux-inspect your cleaned block to detect any existing cracks. That's all that most do, though. But we then sonic-check the cylinder wall thickness for blocks used in our crate engines to ensure it doesn't suffer from core shift or voids that could lead to cracking in the future. Acceptable blocks are then align-honed to precisely locate the crankshaft centerline, as it's the reference point against which all other dimensions, surfaces, and angles are measured. But unlike other shops, our align-honing process begins with ensuring precise and repeatable fitment of the main caps to the block using custom Nitemare-specific dowel pins, to prevent movement of the caps during the machining and rebuilding processes or later during operation. We now have our own Sunnen CK-10 cylinder hone to bore and hone cylinders, which we perform with our custom, stepped deck plate that accurately simulates the clamping loads of Pontiac cylinder heads, to accurately distort the block in the same way it will be once fully assembled, so that the cylinders will be round during operation for ideal ring seal and piston-to-wall clearances. Each block is then fitted to our state-of-the-art Rottler S85A CNC-controlled resurfacing machine which enables us to provide the ultimate milled surface finish for the decks. Combined with our BHJ block fixtures and BHJ Block True kit the deck surfaces of every Nitemare Performance-prepped block will exhibit absolute deck accuracy. The result? All the machined surfaces of your block will be perfectly flat, true, and precisely aligned and located. Blocks are thoroughly deburred and the front oil gallery holes are tapped for 3/8-inch NPT pipe plugs, to prevent loss of oil pressure due to a factory-style pressed-in cap becoming displaced. [ Learn more about our Blueprinted Pontiac Engine Blocks! ] PERFECTLY PREPPED HEADSYour Pontiac heads receive the same obsessive level of attention as your block. Depending on how you want them prepared, we start by porting your cleaned and crack-free heads, then fit them to our SuperFlow SF-450 Flow Bench to verify that they meet whichever flow level you've selected: Stage 1, Stage 2, or positively awesome Stage 3. After porting, each head is secured in our Rottler SG7MTS seat and guide station where each guide is properly located before each seat is cut with our custom 3-angle valve job to maximize air flow and cylinder sealing. The seat work pairs perfectly with the exact dual-angle valve preparation we perform using our Rottler VR10 valve resurfacer. Once the porting, seat, and valve work is finished, we use more BHJ head fixtures to locate every Pontiac head precisely by the dowel pin holes in our Rottler S85A mill. From there each deck is leveled, both front to back and left to right, to ensure an optimal sealing surface for your head gaskets. Once the deck is resurfaced, the head can be rotated exactly 90 degrees to properly true the intake surface, relative to the deck surface. The head is then rotated again to true up the exhaust port mating surfaces. ALL this is obtained with one main set up of our BHJ Head rollover fixture. We can even mill your Pontiac V8's valve cover mating surfaces to improve oil sealing. IT'S WHAT'S INSIDE THAT COUNTSAll our engines feature a full suite of the components that we design and engineer in-house, selected specifically to maximize power, efficiency, and reliability for your individual engine. And while our proven crate engine packages provide outstanding performance and value, if you have specific needs, we're happy to customize an engine to achieve your goals or satisfy race sanctioning body rules. Just give us a call at (203) 239-6868 or email us at info@nitemareperformance.com. Email: info@nitemareperformance.com or call (203) 239-6868  |

|